I really dislike painting, because I am a too impatient and often mess up my own work so I have to go over each thing so many times. It is my own fault and a habit I need to get out of… and I am getting there slowly. I would also like to start using an airbrush rather than rattle cans but it is a lot of money to spend and is something I need to get a lot of advice on. One thing about modding is if you don't know – ask.

Although I do take a lot of time, I am usually happy with my paint work and this is my general process.

First I figure out how I am going to spray everything. Pretend that you are spraying the item and figure out what you need to hit with the spray and how you are either going to rotate the item, or rotate yourself around the item - you don't want to touch it once it is wet. I saw four little caps that needed doing for the CPU block and I just made a really quick painting block out of a bit of wood and a few screws. I offset the screws so that I could hit the caps from every angle easier.

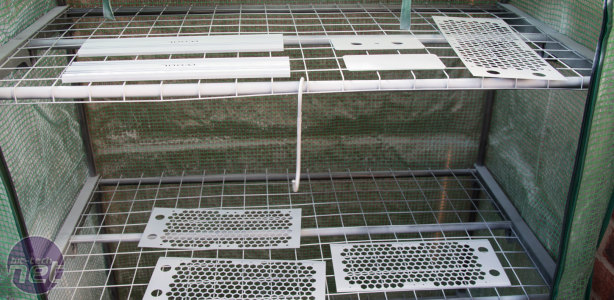

For bigger items you can use shelving like this that can be picked up from gardening centres inexpensively. I actually got this idea from Antony Leather who is a big contributor to bit-tech and does some of our reviews. It is a great idea and far better than the shelves I previously used. Here I have just given the radiator parts a good few coats of primer, later I will coat them in paint, then a clear coat.

Sometimes hooks can help you when you are spraying, and I bought a bag of them for just a few pounds and they help when trying to cover everything. Once it had been primed, painted and clear coated, it is very similar to the powder-coated case.

After taking these pictures, I noticed that the edge of the radiator hasn't been coated very well, so I have got to go back and just touch that up. It is only one small piece and with this radiator being so easy to take apart, it won't take me a long time. I thought I had actually done all of the edges a few times, but you can see I missed one. When you reassemble parts you have painted, be careful, because you don't want to ruin all your hard work by rushing.

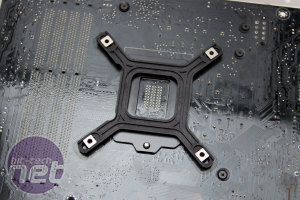

As the bracket for the CPU block was finished before the cover for it was, I was able to put the block on the motherboard. It is quite simple and is just like fitting an air cooler, just pop the bracket on the back and then use the screws, washers and springs to ensure a good contact, but obviously you need to make sure that you have applied thermal paste first.

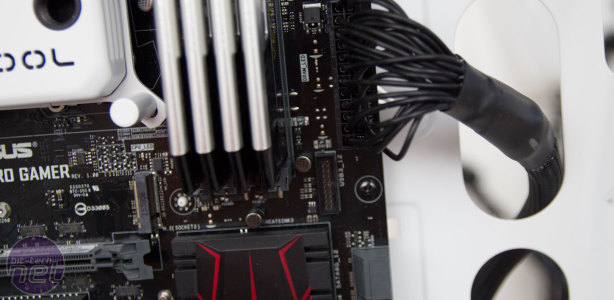

Once the cover was dry I popped it onto the CPU block, and it looks rather tasty in white! I actually popped a picture of this to the Alphacool rep and they mentioned they were going to see if it is possible to make some in white. If this happens, I will edit this part to ensure you don't spend time on something you can purchase.

One thing that always looks ugly on cases are the openings for cables, even with grommets they are usually horrible. It isn't the case manufacturers’ fault, because they have to make them so that you can push your wires through, but with so many different motherboards on the market and other variables, we are usually left with a motherboard tray with multiple holes that are not used.

I decided to make a quick acrylic cover to hide the holes and make things look a little bit tidier. I used a bit of 3mm matte white Perspex and cut it so it went behind the motherboard by around 3mm, meaning none of the edges will be seen. The top edge has been left short so it can be removed easily, as it won’t be seen when it is finished, if you don't want an edge like this, then simply remove a few panels from the case before fixing it in place.

Obviously I still need to pass cables through the panel, so I need to drill some holes. I used a 20mm hole-cutter right next to the IO panel, and this will ensure that all those hanging cables are out of the way almost instantly. It did mean cutting a hole into the motherboard tray as well, but it is worth it.

I also needed to cut holes for the 24pin, SATA cables and fans. Once all the holes were cut, I used a file to straighten out all the edges and remove the excess bits and then applied some 2,000-grit wet and dry around the edge to ensure that it is very smooth. We don't want the sharp acrylic cutting through the wires.

This is where I am going to leave it for today. The next part of this little build is going to show the PSU sleeving, fitting the liquid cooling and also finishing the build. It is going to be interesting as space is a little tight, especially with the big, chunky radiator, but we will figure it out eventually. Hopefully you can see how it is starting to take shape and can see what I am trying to do. Let me know what you all think.

Check out part 3 Here

Although I do take a lot of time, I am usually happy with my paint work and this is my general process.

First I figure out how I am going to spray everything. Pretend that you are spraying the item and figure out what you need to hit with the spray and how you are either going to rotate the item, or rotate yourself around the item - you don't want to touch it once it is wet. I saw four little caps that needed doing for the CPU block and I just made a really quick painting block out of a bit of wood and a few screws. I offset the screws so that I could hit the caps from every angle easier.

For bigger items you can use shelving like this that can be picked up from gardening centres inexpensively. I actually got this idea from Antony Leather who is a big contributor to bit-tech and does some of our reviews. It is a great idea and far better than the shelves I previously used. Here I have just given the radiator parts a good few coats of primer, later I will coat them in paint, then a clear coat.

Sometimes hooks can help you when you are spraying, and I bought a bag of them for just a few pounds and they help when trying to cover everything. Once it had been primed, painted and clear coated, it is very similar to the powder-coated case.

After taking these pictures, I noticed that the edge of the radiator hasn't been coated very well, so I have got to go back and just touch that up. It is only one small piece and with this radiator being so easy to take apart, it won't take me a long time. I thought I had actually done all of the edges a few times, but you can see I missed one. When you reassemble parts you have painted, be careful, because you don't want to ruin all your hard work by rushing.

As the bracket for the CPU block was finished before the cover for it was, I was able to put the block on the motherboard. It is quite simple and is just like fitting an air cooler, just pop the bracket on the back and then use the screws, washers and springs to ensure a good contact, but obviously you need to make sure that you have applied thermal paste first.

Once the cover was dry I popped it onto the CPU block, and it looks rather tasty in white! I actually popped a picture of this to the Alphacool rep and they mentioned they were going to see if it is possible to make some in white. If this happens, I will edit this part to ensure you don't spend time on something you can purchase.

One thing that always looks ugly on cases are the openings for cables, even with grommets they are usually horrible. It isn't the case manufacturers’ fault, because they have to make them so that you can push your wires through, but with so many different motherboards on the market and other variables, we are usually left with a motherboard tray with multiple holes that are not used.

I decided to make a quick acrylic cover to hide the holes and make things look a little bit tidier. I used a bit of 3mm matte white Perspex and cut it so it went behind the motherboard by around 3mm, meaning none of the edges will be seen. The top edge has been left short so it can be removed easily, as it won’t be seen when it is finished, if you don't want an edge like this, then simply remove a few panels from the case before fixing it in place.

Obviously I still need to pass cables through the panel, so I need to drill some holes. I used a 20mm hole-cutter right next to the IO panel, and this will ensure that all those hanging cables are out of the way almost instantly. It did mean cutting a hole into the motherboard tray as well, but it is worth it.

I also needed to cut holes for the 24pin, SATA cables and fans. Once all the holes were cut, I used a file to straighten out all the edges and remove the excess bits and then applied some 2,000-grit wet and dry around the edge to ensure that it is very smooth. We don't want the sharp acrylic cutting through the wires.

This is where I am going to leave it for today. The next part of this little build is going to show the PSU sleeving, fitting the liquid cooling and also finishing the build. It is going to be interesting as space is a little tight, especially with the big, chunky radiator, but we will figure it out eventually. Hopefully you can see how it is starting to take shape and can see what I am trying to do. Let me know what you all think.

Check out part 3 Here

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.